Built with the best Open-Source technology available in the market, Manufacturing Analytics is seamlessly integrated into one platform to make digitalization projects more effective and flexible.

Manufacturing Analytics relies only on recognized standards by the market, thus guaranteeing industrial reliability.

Deployed with Docker technology, the Manufacturing Analytics platform connects to multiple manufacturing data sources: Process Automation, MES, ERP, LIMS,…. and centralizes all the data to transform it into operational information. The platform is ready to meet your operational needs and the requirements of your IT team.

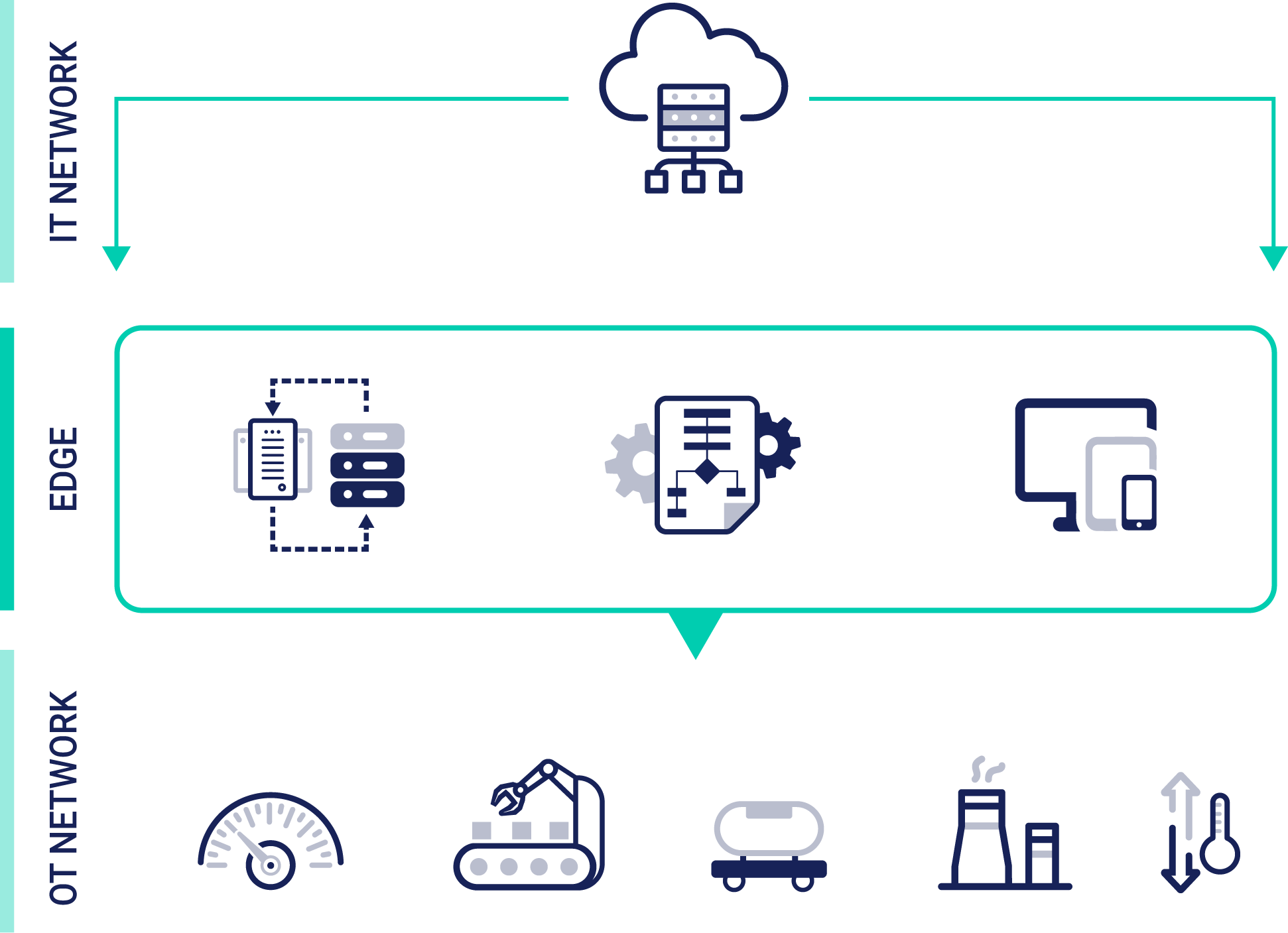

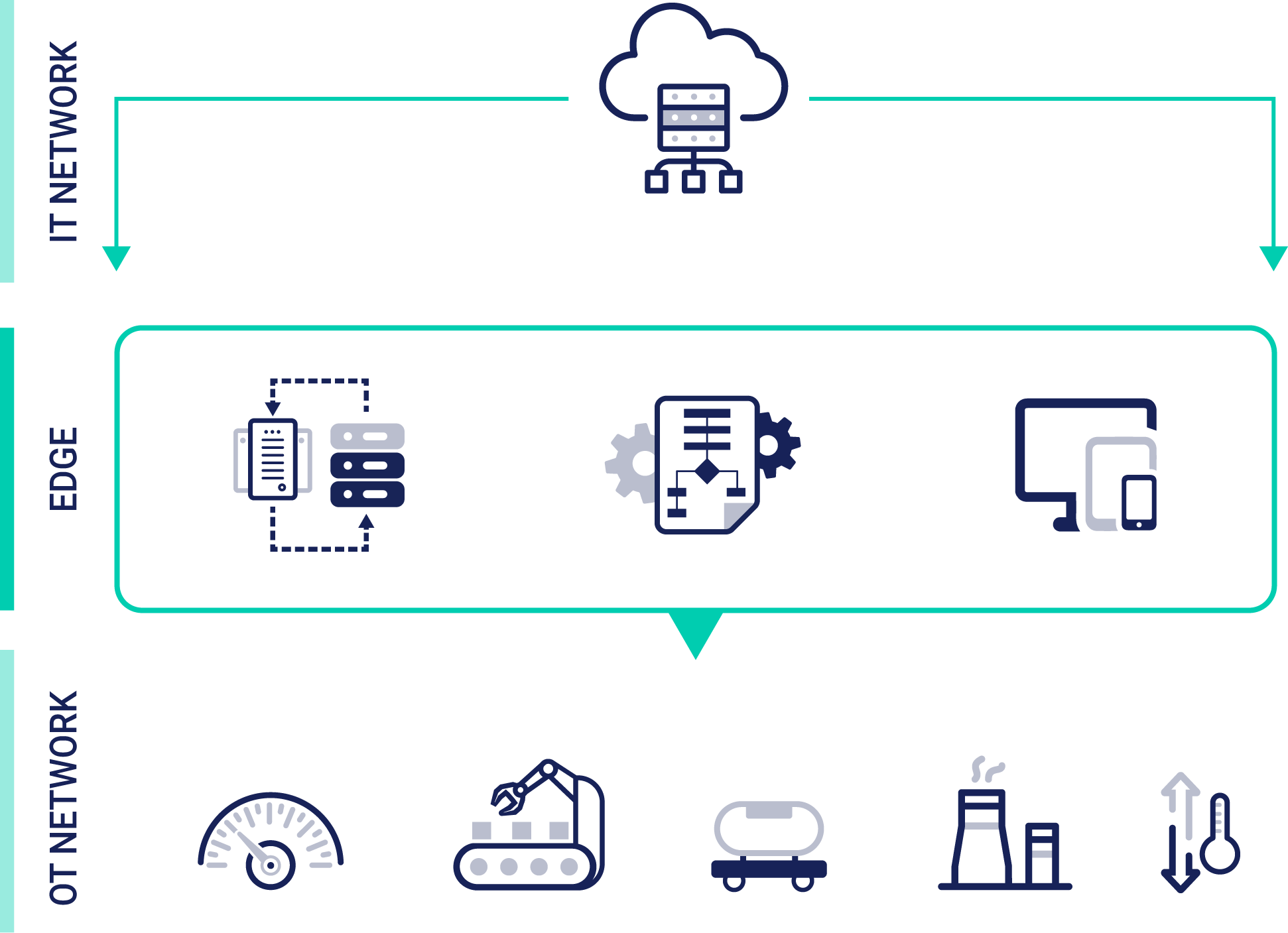

Our Edge Computing solution allows you to connect with any kind of industrial device at the shopfloor and extract data from IT systems like MES, ERP, LIMS,… to centralize all the data and carry out joint exploitation.

Edge devices are designed to live halfway between the Operational Technology network and the Information Technology network of your business. They collect, transform and send your factory operations data from any data source over a standard IoT communication protocol to an upper secure storage layer.

Our Edge Computing solution allows you to connect with any kind of industrial device at the shopfloor and extract data from IT systems like MES, ERP, LIMS,… to centralize all the data and carry out joint exploitation.

Edge devices are designed to live halfway between the Operational Technology network and the Information Technology network of your business. They collect, transform and send your factory operations data from any data source over a standard IoT communication protocol to an upper secure storage layer.

Edge devices are designed to live halfway between the Operational Technology network and the Information Technology network of your business.

Bringing the computing capacity down to machine level in a distributed manner allows us to perform better data processing, historization and visualization tasks suitable for manufacturing operations pursuing maximum efficiency.

Basic tasks of data validation and historization of raw data are distributed to the Edge devices, process KPIs are calculated in real time right next to the machine and only the most important data is uploaded to the upper secure storage layer for advanced analytics.

Communication between the Edges and Cloud layers are secured by the Encrypted Communication Protocol (MQTTS) that allows you the segmentation of your OT and IT networks. Cybersecure!

Don´t be concerned about data privacy, the entire path your industrial operations data will take, from the machine to analysis dashboards, is secured with encrypted communication protocols. Manufacturing analytics only work with industry regulations complying data-warehouses, ensuring that your data always will be protected.

Communication between the Edges and Cloud layers are secured by the Encrypted Communication Protocol (MQTTS) that allows you the segmentation of your OT and IT networks. Cybersecure!

Don´t be concerned about data privacy, the entire path your industrial operations data will take, from the machine to analysis dashboards, is secured with encrypted communication protocols. Manufacturing analytics only work with industry regulations complying data-warehouses, ensuring that your data always will be protected.